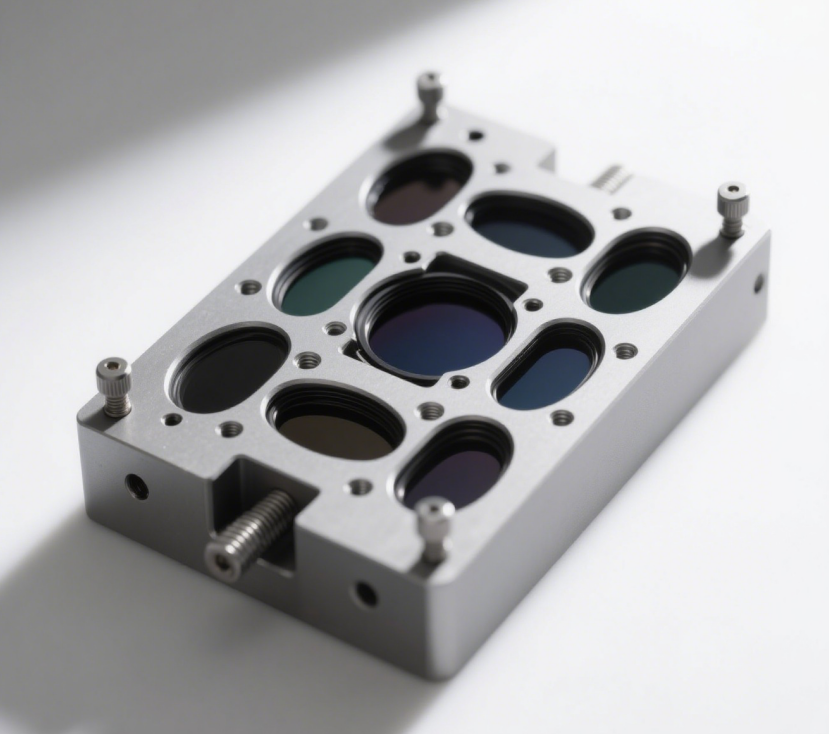

Lens packing mould

1. Product Overview

Designed for large optical lenses, this mould uses precision thermoforming for PET/PC sheets, forming shockproof blisters for 50-300mm diameter lenses. Balances high transmittance and protection for eyewear and optical instrument lenses.

2. Core Features

(1) Large-size Precision Positioning

Elastic buffer with vacuum adsorption, fixing error ≤0.1mm, withstands 8kg impact.

(2) Optical-grade Mirror Finish

Magnetic polished cavity (Ra≤0.2μm), blister transmittance ≥93%, scratch-free for AR-coated lenses.

(3) Efficient Temperature Control

Dual-channel heating + spiral cooling, 120-180℃±2℃, 12s/cycle, 10,000 pcs daily output.

(4) Quick-release Frame

6-guide pillar pneumatic design, 5-min module change, 0.1mm thickness adjustment.

3. Technical Parameters

Parameter Type | Specific Value |

Sheets | PET/PC (0.5-2.0mm) |

Mould Size | 600×500×400mm (custom) |

Temp Range | RT-180℃ |

Forming Pressure | 0-20 tons |

Positioning Acc | ±0.15mm |

Light Transmittance | ≥93% |

4. Applications

Eyewear lenses: large myopia/sunglass lenses with anti-scratch lining

Optical instruments: camera/telescope lens ESD packaging

Special lenses: laser lens sealed blisters with nitrogen filling

5. Customization

Curvature design for convex/concave lenses

Antistatic coating (10⁶-10⁹Ω surface resistance)

Automated positioning for production lines

6. Quality Assurance

ISO 9001 certified, CMM-inspected

12-month warranty, 24h response

Wear parts at cost price