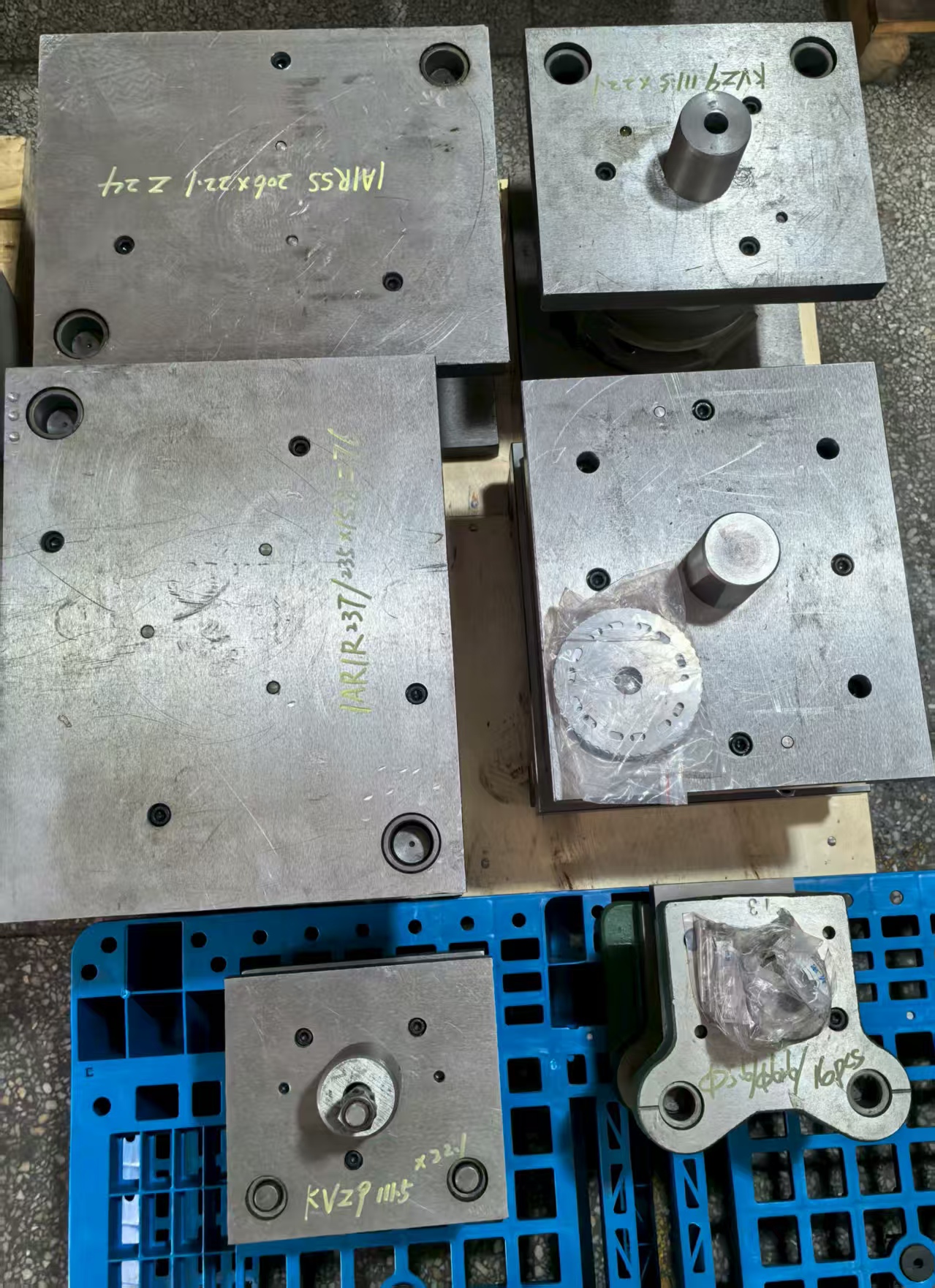

Saw Blade Steel Core Stamping Mould

Product Overview

This stamping mould for saw blade steel cores is specially designed for high-precision stamping of metal saw blade cores, adopting cold stamping technology and multi-station progressive die structure. Optimized for carbon steel, alloy steel and other core materials, it achieves efficient stamping production at room temperature, with high-precision hole and edge forming capabilities, suitable for large-scale production of 100-1200mm saw blade cores.

Product Features

Multi-station Progressive Stamping Technology:12-station continuous stamping completes blanking, punching, slotting, rib pressing in one go, with production tempo up to 15 cycles/min, 80% higher efficiency than single-process moulds, material utilization rate up to 75%.

High-wear Resistance Die Steel:Punch and die use SKD11 die steel with vacuum quenching + cryogenic treatment, surface hardness HRC62-65. With TD coating, abrasive wear resistance increases 5 times, enduring over 500,000 stamping cycles, 3× longer mould life than traditional materials.

Precision Guiding Positioning System:Four-guide pillar precision guiding + ball bushing structure with laser positioning, hole position accuracy within ±0.03mm, core radial runout ≤0.05mm, meeting dynamic balance requirements for high-speed cutting.

Integrated Automatic Feeding Design:The mould integrates CNC feeding mechanism and waste recycling system, feeding accuracy ±0.1mm, supporting coil continuous stamping, reducing manual intervention, compatible with automated production lines.

Technical Parameters

Parameter Type | Specific Value |

Applicable Saw Blade Diameter | 100mm-1200mm (core thickness 0.8mm-5mm) |

Working Pressure Range | 0-200 tons (servo hydraulic drive) |

Mould Closing Height | 300mm-500mm (adjustable) |

Mould Size | Standard type 1500mm×800mm×450mm (customizable) |

Material Combination | Punch & die (SKD11 + TD coating) |

Die set (45# steel aged treatment) |

Application Areas

Metal Processing Industry:Bulk stamping of carbon steel/stainless steel saw blade cores;

Stone Cutting Tools:High-precision processing of granite/marble cutting saw cores;

Construction Engineering Tools:Production of concrete cutting saw cores, asphalt pavement joint saw cores;

Woodworking Machinery:Manufacturing of saw blade cores for solid wood processing and composite panel cutting.

Customization Services

Customizable core diameter, center hole diameter, cooling slot shape;

Support for tooth shape customization (flat/wave/ladder teeth) to adapt to different cutting needs;

Optional mould surface coatings (TiN/TiCN) to reduce friction loss during stamping.

Quality Assurance

Complies with ISO 9001:2015, each mould undergoes three aging treatments to eliminate internal stress;

Three-coordinate measuring instrument detects mould precision, key dimensions within ±0.02mm tolerance;

12-month warranty, free replacement of punch & die components for non-human damage, lifelong cost-price supply for wearing parts.