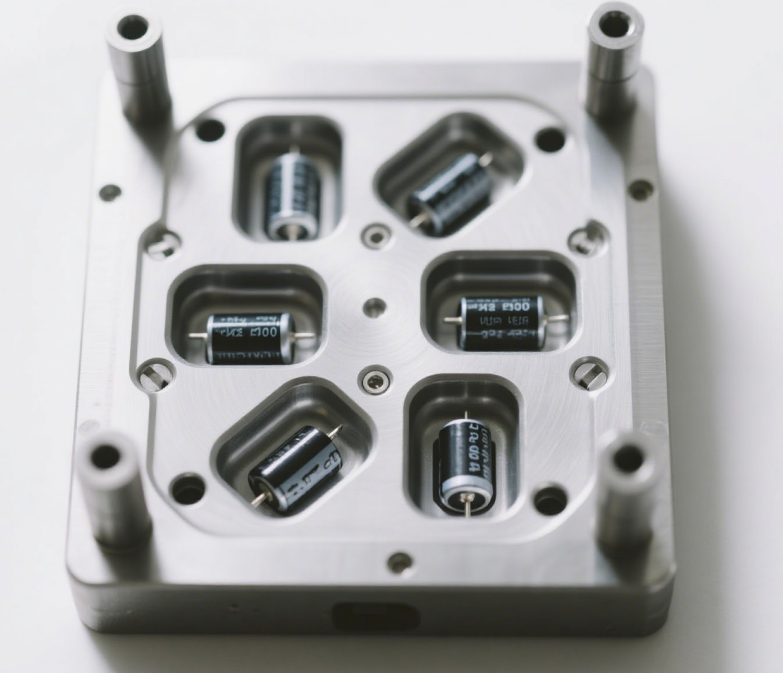

Capacitance packing mould

1. Product Overview

Designed for thermoforming of capacitor blisters in electronics, this mould adopts precision hot pressing for ESD-safe sheets like PVC/PET-G. It achieves precise forming for 0402-2225 package capacitors, balancing ESD protection and automated production line compatibility.

2. Core Features

(1) Micro Shockproof Design

Honeycomb buffer ribs with ESD closure edges withstand 10kg impact, fixing capacitors with ≤0.1mm error.

(2) ESD Mirror Finishing

S136H ESD steel with EDM polishing (Ra≤0.3μm), blister surface resistance 10⁶-10⁹Ω compliant with ESD standards.

(3) Rapid Temperature Control

Dual-channel ceramic heaters with PID control (120-180℃±3℃), 15s/cycle cycle time, 20,000 pcs daily capacity.

(4) Modular Quick-release

4-guide pillar pneumatic clamping, 5-min module change, 0.05mm thickness adjustment for multi-spec capacitors.

3. Technical Parameters

Parameter Type | Specific Value |

Sheets | PVC/PET-G (0.15-0.8mm) |

Mould Size | 400×300×250mm (custom) |

Temp Range | RT-180℃ |

Forming Pressure | 0-15 tons |

Positioning Acc | ±0.08mm |

ESD Resistance | 10⁶-10⁹Ω |

4. Applications

Tape & reel capacitor blisters with auto-loading slots

Electrolytic capacitor shockproof blisters for radial/axial leads

ESD blisters for high-frequency capacitors with aluminum shielding

5. Customization

ESD resistance level customization (10⁶-10¹²Ω)

Precision tape hole design (±0.05mm tolerance)

Automated pad positioning structure development

6. Quality Assurance

ISO 9001:2015 compliant, CMM-inspected key dimensions

12-month warranty, lifetime ESD coating maintenance

24-hour response for electronics industry special requirements