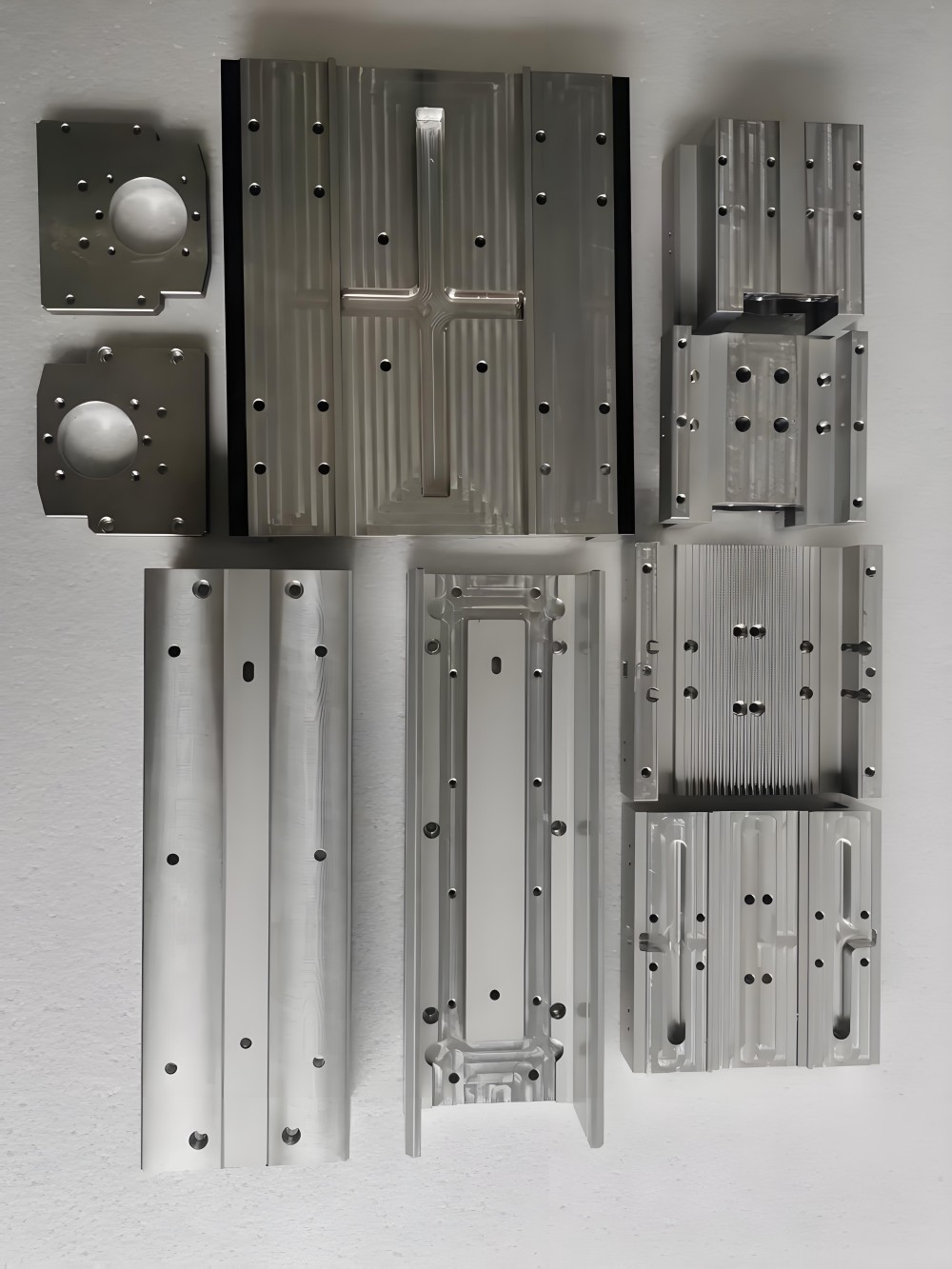

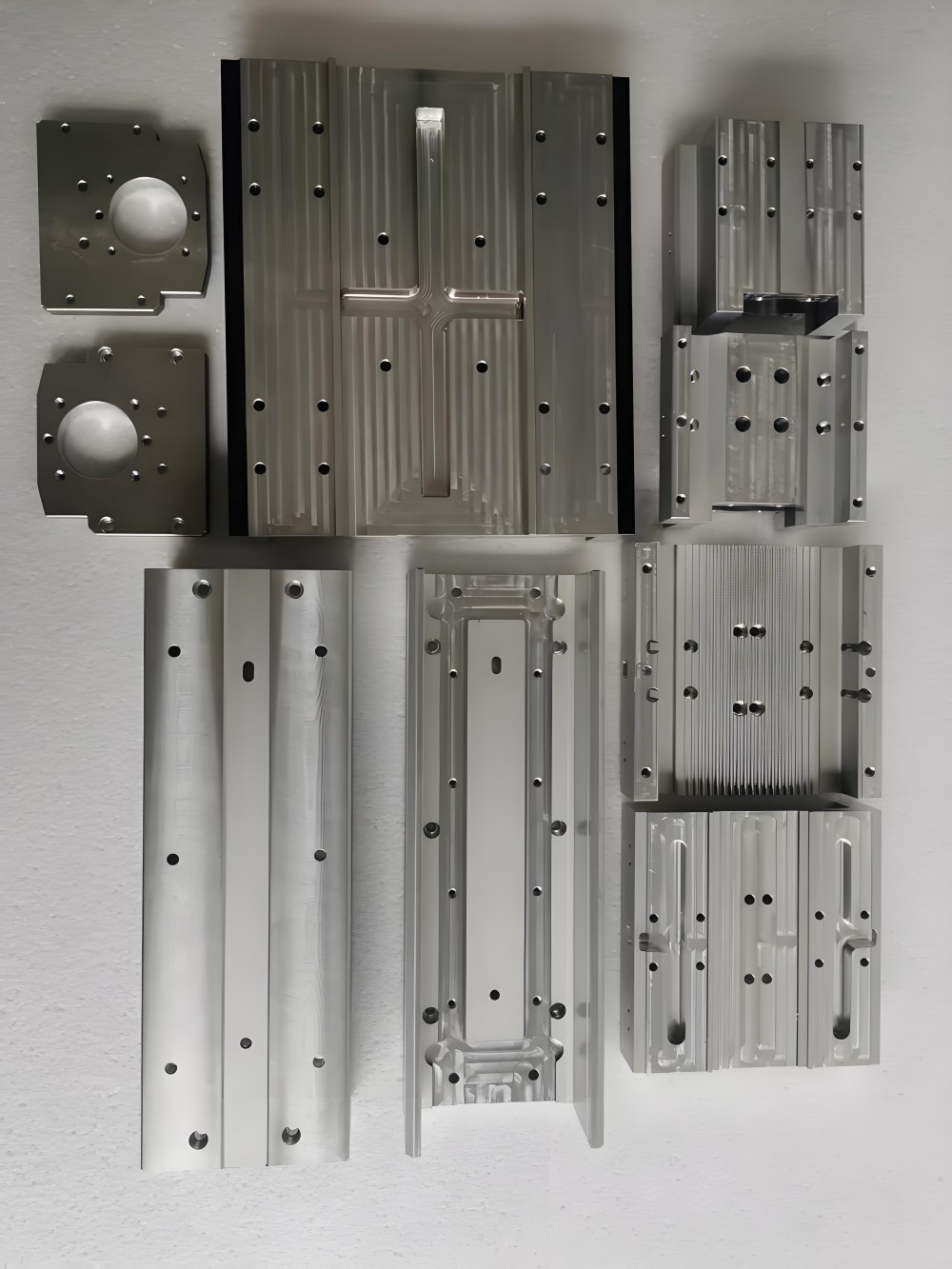

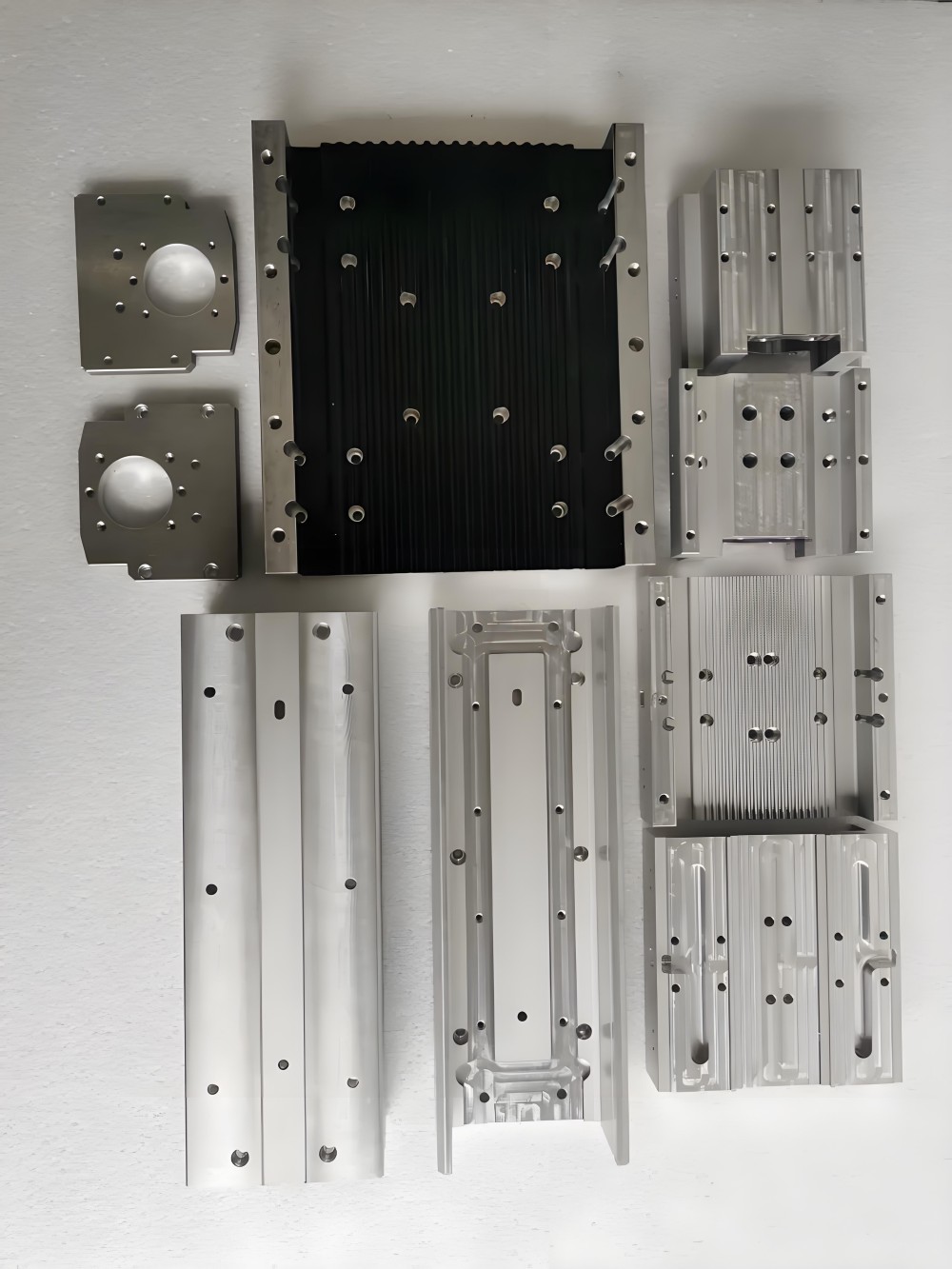

Sliding Table Module Parts

1. Product Overview

Designed for precision linear motion systems, these parts use 6061-T6 aluminum/45# steel with CNC machining and surface hardening, enabling high-rigidity linear components. They balance load capacity and motion accuracy for single/multi-axis modules in automation, semiconductor, and medical equipment.

2. Core Features

(1) High-strength Lightweight Structure

6061-T6 aluminum body (tensile ≥310MPa), GCr15 bearing steel guides (≥60HRC)

Optimized profile increases load capacity by 20% while reducing weight by 30%

(2) Micron-level Motion Accuracy

Linear guide mounting surface flatness ≤0.02mm/100mm

Ball screw lead accuracy C7 grade, repeat positioning ±0.05mm

(3) Wear-resistant Surface Treatment

Aluminum parts hard anodized (15-25μm, ≥300HV)

Steel parts quenched + chrome plated (8-12μm coating)

(4) Quick-mount Structure Design

Standardized mounting holes (ISO 261 compatible)

Modular components allow ≤10-min disassembly, 50% faster maintenance

3. Technical Parameters

Parameter Type | Specific Value |

Stroke Range | 100-2000mm (custom) |

Load Capacity | 5-100kg (horizontal) |

Max Speed | 1-5m/s (motor-dependent) |

Positioning Acc | ±0.05mm (repeat) |

Guide Type | Linear rolling/sliding |

4. Applications

3C Manufacturing: Phone screen bonding machines, PCB handling modules

Medical Equipment: CT scanner slides, surgical robot platforms

Aerospace: Satellite antenna adjusters, UAV gimbal mounts

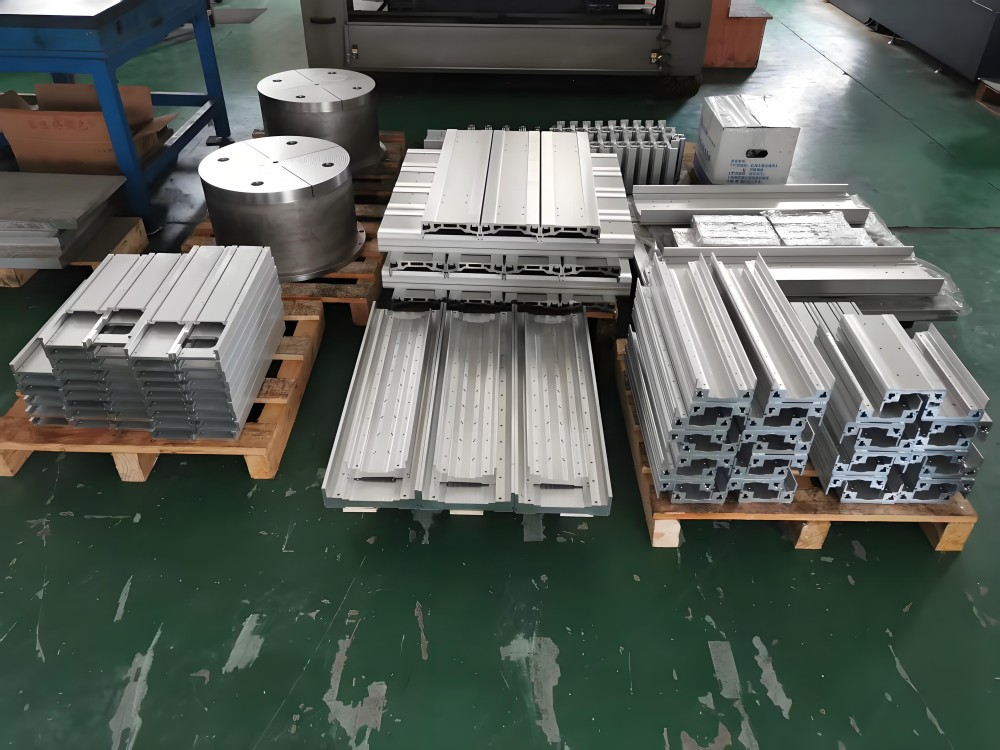

5. Customization

Stroke dimension customization (±0.1mm tolerance)

Mounting interface adaptation (compatible with different motors)

Dust/waterproof design (IP54/IP65 protection)

6. Quality Assurance

CMM-inspected with precision report for each batch

surface treatment thickness check (±2μm error)

12-month warranty with free installation guidance