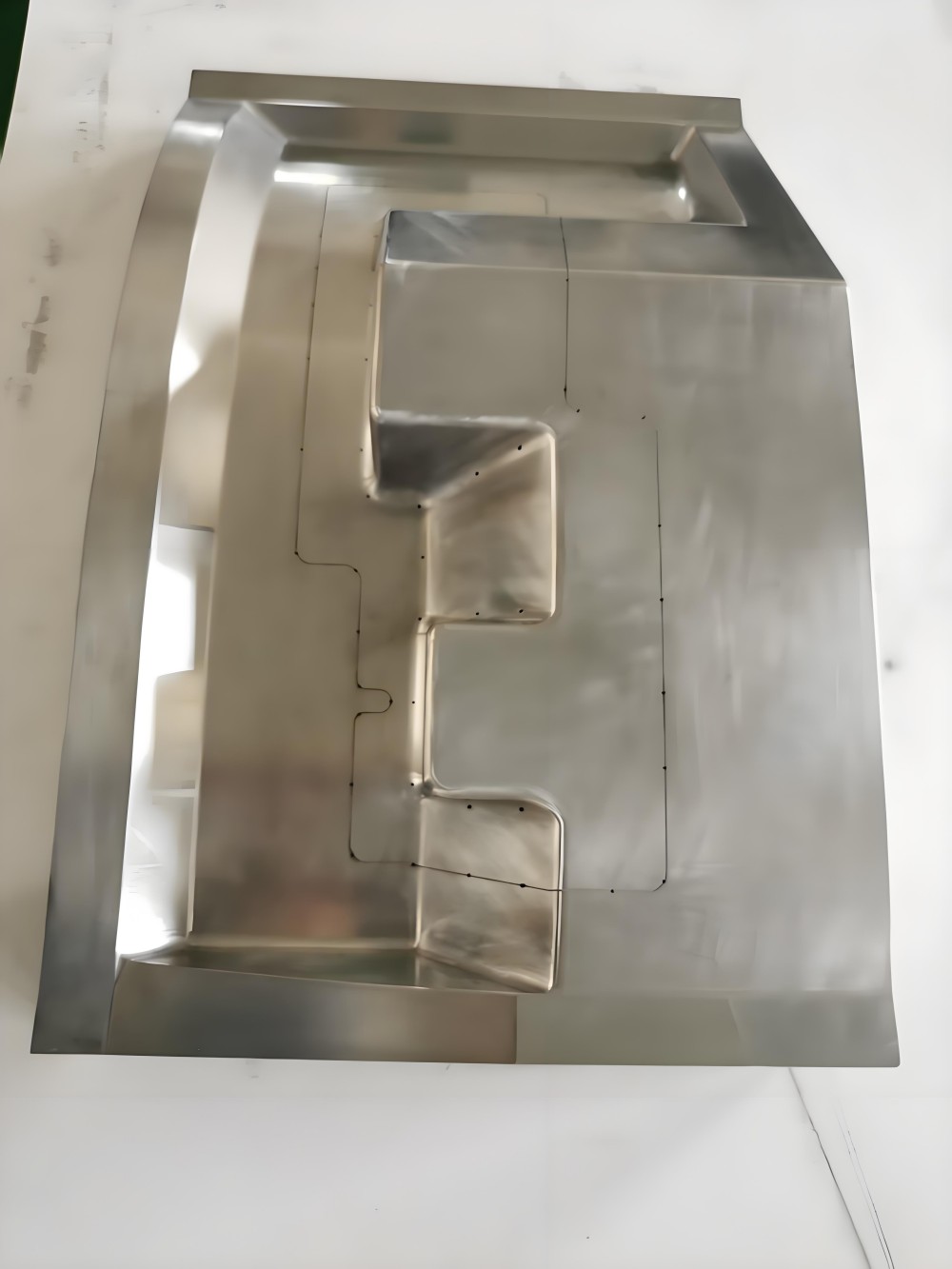

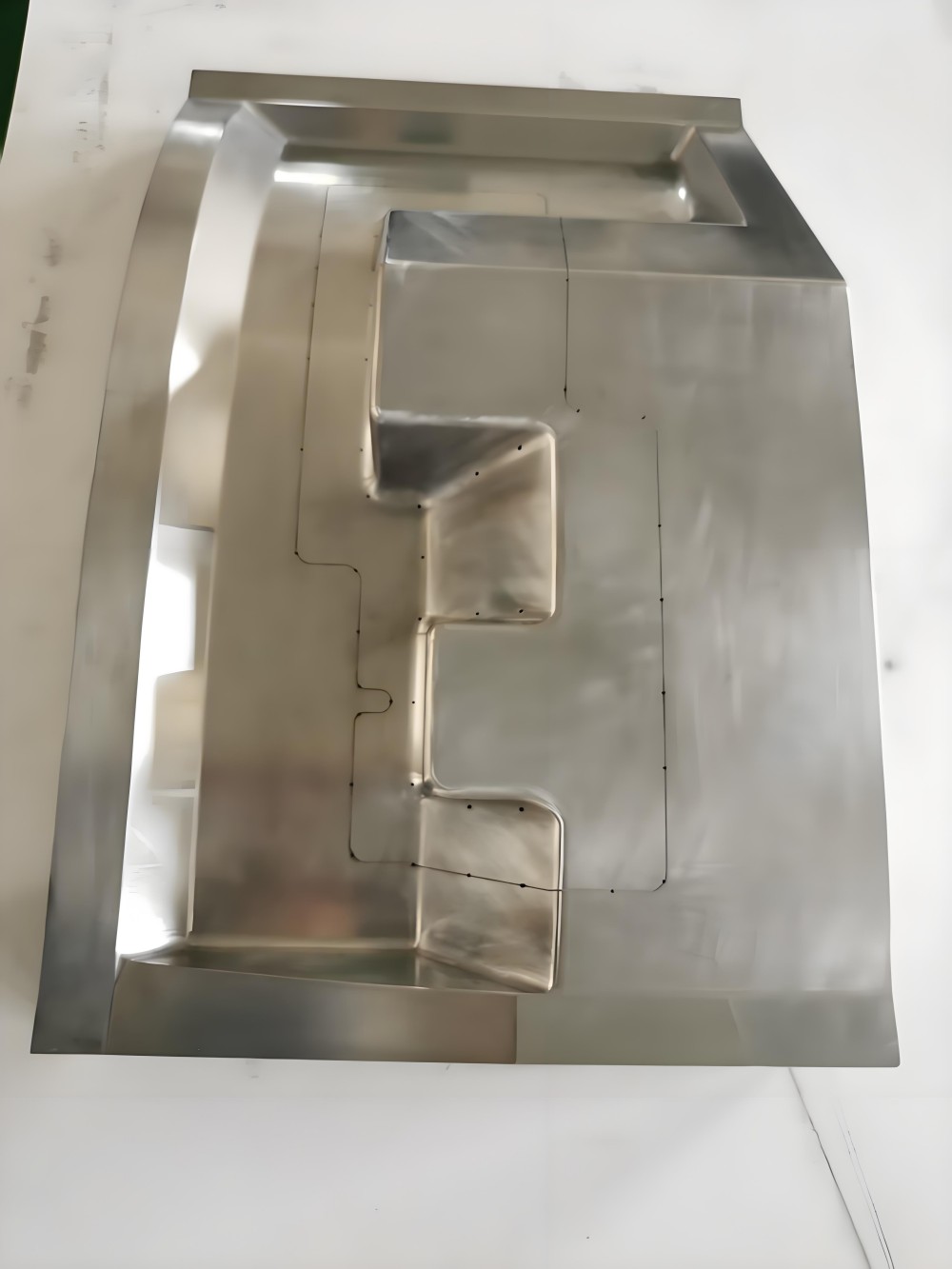

Car interiors thermoforming mould

Product Features

Five-zone Independent Temperature Control:Built-in ceramic heating rods combined with copper alloy heat-conducting plates, achieving precise temperature control of ±2℃ within 180-240℃ via PLC intelligent module, with temperature deviation ≤±3℃ between zones, ensuring uniform sheet softening and avoiding material degradation from local overheating.

High-temperature Resistant Material:The cavity uses H13 hot work die steel with vacuum quenching + cryogenic treatment, surface deposited with TiAlN hard coating (5μm thickness), capable of withstanding 250℃ cycles over 10,000 times, mold thermal deformation ≤0.05mm, ensuring dimensional stability in long-term production.

Bionic Curved Forming Structure:Based on ergonomic design of automotive interiors, the mould adopts a combination of segmented elastic blank holders and conformal cooling channels, supporting one-time forming of complex curves with radius ≥5mm, part springback ≤0.3% after demoulding, meeting Class A surface quality requirements.

Automated Integration System:Standard infrared positioning feeding mechanism and robot picking system, feeding accuracy ±0.1mm, production tempo 8-12 cycles/min. Integrated with waste recycling and mold cleaning devices, reducing manual intervention, suitable for Industry 4.0 smart factory layouts.

Technical Parameters

Parameter Type | Specific Value |

Applicable Sheet Thickness | 0.8mm-5mm (PP/ABS/PC composites) |

Working Temperature Range | Room temperature-240℃ (five-zone independent control) |

Hot Pressing Pressure | 0-150 tons (servo hydraulic closed-loop control) |

Mould Size | Standard type 1500mm×1000mm×800mm (customizable) |

Material Combination | Cavity (H13 + TiAlN coating) |

Heating layer (copper alloy + ceramic heating rods) |

Application Areas

Dashboard Forming:Hot pressing of rigid dashboards and base materials for slush-molded dashboards, supporting integration of air vents, button mounting holes, etc.;

Door Interior Panels:Complex curved forming of door armrests and decorative panels, simultaneously completing functional structures like snap holes and wire harness holes;

Center Console Parts:High-gloss and mark-free forming of center console panels and shift panels, suitable for surface treatments like piano black and matte textures;

Roof Interiors:Hot pressing of roof handles and sun visor base materials, supporting composite processing with fabric materials.

Customization Services

Deep Shape Customization:Based on customer-provided 3D models (UG/CATIA format), providing parting surface design, mold flow analysis, and forming scheme optimization;

Surface Texture Customization:Engraving decorative textures like leather grain and carbon fiber pattern, supporting integration of in-mold decoration (IMD/IML) processes;

Special Function Development:Custom electromagnetic heating modules and laser online detection systems for integrated thermoforming and online inspection.

Quality Assurance

Complies with IATF 16949 automotive quality management system, each mould undergoes three high-temperature aging treatments, with fluorescent flaw detection for internal defects;

Formed parts inspected by CMM, key dimensions controlled within ±0.1mm, surface roughness Ra≤0.4μm;

18-month warranty provided, free replacement of heating modules for non-human damage, lifelong cost-price supply for wearing parts, including 3 free mold temperature system calibrations.