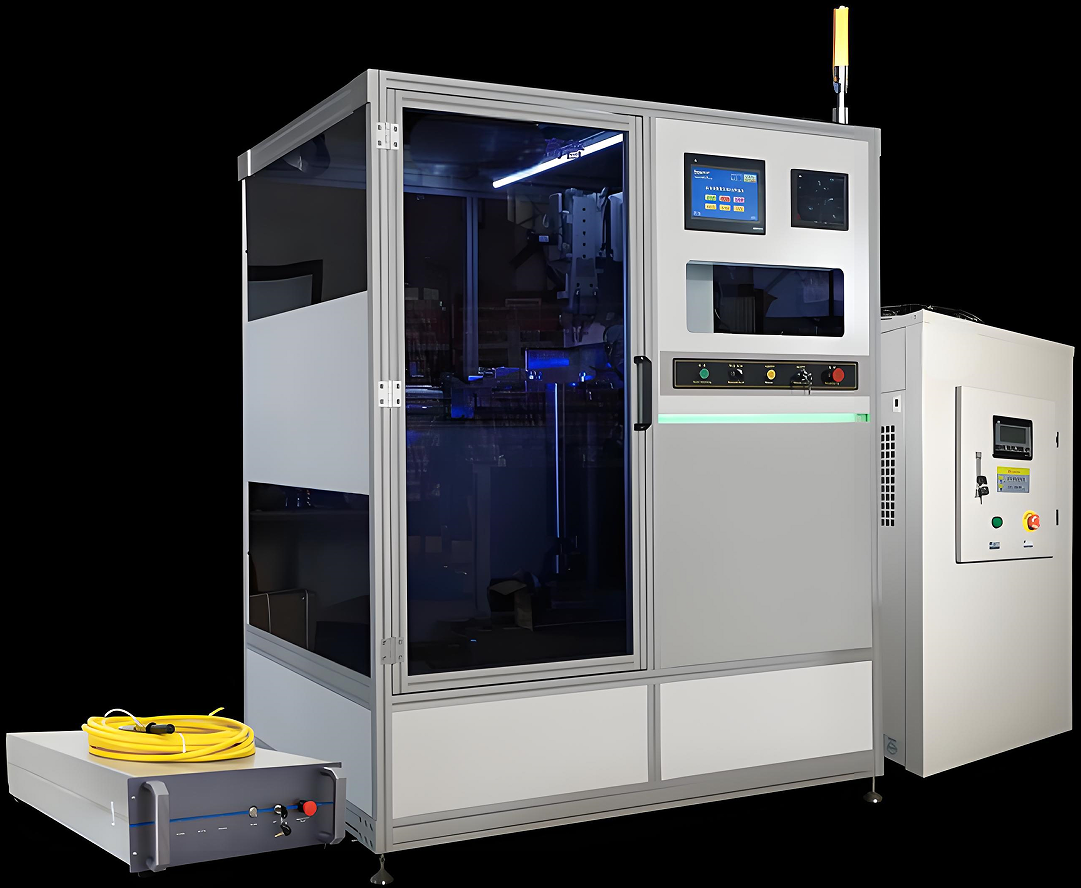

Auto Core Drill Welding Machine

1. Product Overview

Designed for automated brazing of carbide core drills, this machine integrates high-frequency induction welding with 4-axis servo system for precision welding. It supports 30-200mm core drills, meeting intelligent welding needs in construction, pipe processing, and stone cutting.

2. Core Features

(1) Full Automation Welding

· 4-axis servo positioning (±0.02mm repeatability) for automatic loading, welding, unloading

· Vision system (0.01mm resolution) for automatic cutter head alignment

(2) High-frequency Induction Heating

· 20-80kHz power supply, single-point welding ≤6s

· Infrared closed-loop control (±2℃) prevents thin-wall drill overheating

(3) Intelligent Production Management

· Stores 50 welding programs with QR code quick calling

· RS485 interface for factory automation system integration

(4) Safety Protection

· Electromagnetic shielding (radiation ≤0.8mG)

· Automatic smoke exhaust (300m³/h airflow) for workshop safety

3. Technical Parameters

Parameter Type | Specific Value |

Welding Power | 15-30kW (adjustable) |

Drill Diameter | 30-200mm |

Production Rate | 120-240 pcs/hour |

Positioning Acc | ±0.03mm |

Power Supply | 3-phase 380V/50Hz |

4. Applications

· Construction: Automated batch welding of concrete core drills

· Pipe Installation: Intelligent welding of metal pipe hole cutters

· Stone Processing: Flowline production of marble/granite core drills

5. Customization Services

· Multi-specification drill compatibility design

· Online welding quality inspection integration

· Unmanned welding cell planning

6. Quality Assurance

· 24-month warranty for key components

· Welding process optimization training provided

· 2h remote response, 24h on-site service (domestic)