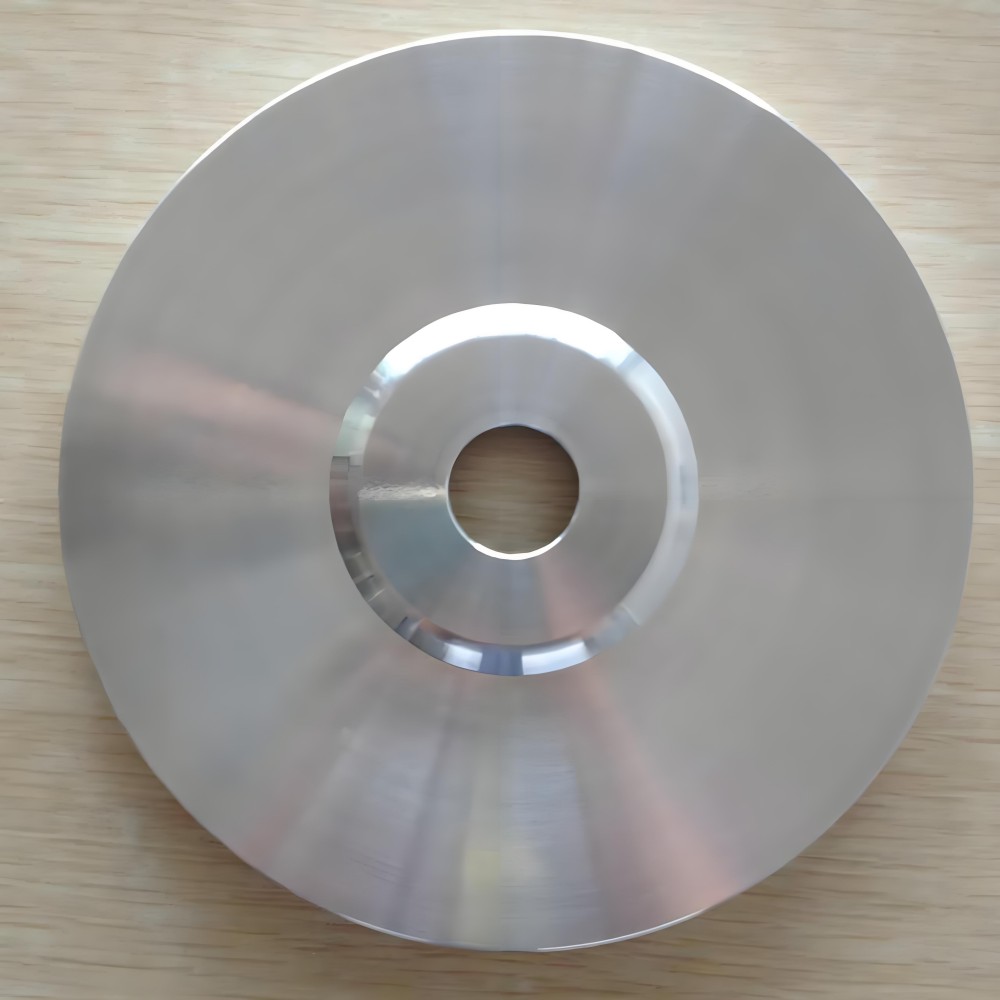

Louver wheel net polishing disc

1. Product Overview

Designed for metal surface polishing, this disc uses 6061-T6 aluminum structure with CNC machining and anodizing, ensuring stable Louver wheel net polishing disc (flap wheel) mounting. The louver design balances heat dissipation and clamping force for 100-300mm flap wheels in automotive, aerospace, and hardware polishing.

2. Core Features

(1) Lightweight High-strength Structure

6061-T6 aluminum (tensile ≥310MPa), 40% lighter than steel

Louvered design improves heat dissipation by 35%, preventing overheating

(2) Precision Clamping System

3-jaw chuck structure, radial runout ≤0.05mm (3000rpm)

Quick-change design, flap wheel replacement ≤15s

(3) Wear-resistant Surface Treatment

Hard anodizing (15-25μm, hardness ≥300HV)

Anti-slip tooth pattern, clamping force ≥80N

(4) Dynamic Balance Optimization

High-speed balancing (residual unbalance ≤5g·mm)

Speed range: 1000-6000rpm

3. Technical Parameters

Parameter Type | Specific Value |

Flap Wheel Diameter | 100-300mm |

Disc Thickness | 15-30mm (customizable) |

Center Hole Diameter | φ16mm/φ20mm (standard) |

Balance Grade | G6.3 (ISO 1940) |

Surface Roughness | Ra≤1.6μm (mounting surface) |

4. Applications

Automotive: Body aluminum polishing with curved disc design

Aerospace: Aluminum profile finishing, balance accuracy ≤0.03mm

Hardware: Stainless steel/copper mirror polishing, multi-spec flap wheel compatible

5. Customization

Hole diameter customization (±0.02mm tolerance)

Special tooth pattern for non-standard flap wheels

Anti-corrosion coating (e.g. Teflon spray)

6. Quality Assurance

Each disc with dynamic balance test report

anodizing thickness inspection (±2μm error)

12-month warranty, free replacement for non-human damage