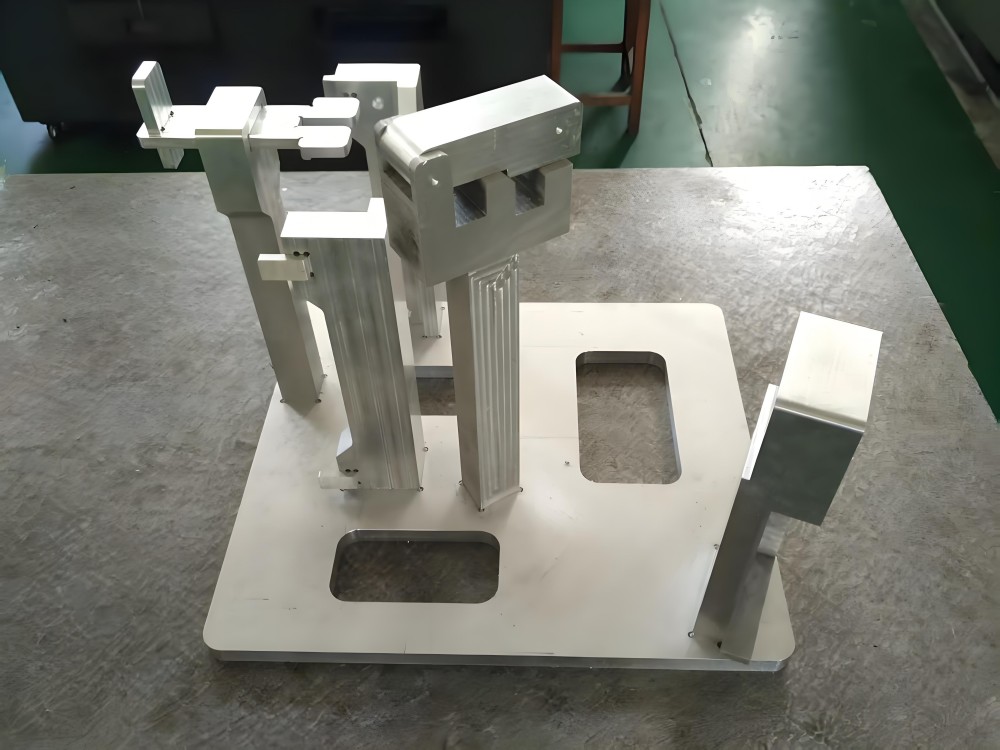

Battery test chucking

1. Product Overview

Designed for automated testing of power and consumer batteries, this chucking uses 6061-T6 aviation aluminum structure, achieving high-precision electrical connection and mechanical fixing via CNC machining and conductive anodizing. It supports cylindrical/prismatic/pouch batteries for cycle life and capacity fade tests in R&D labs and production lines.

2. Core Features

(1) Low-resistance Conductive Structure

Copper-aluminum composite contacts (surface resistance ≤0.5mΩ)

Conductive anodizing (1-3μm) ensures ≤5% resistance fluctuation after 100,000 insertions

(2) Micron-level Positioning

5-axis CNC machined slots (tolerance ±0.03mm) for ±0.1mm tab alignment

Elastic clamping compensates battery size variation (±0.5mm)

(3) Aging-resistant Design

T6 heat-treated aluminum (hardness ≥130HB) withstands 200℃

PEEK insulating parts (≥1000V withstand voltage), UL94-V0 compliant

(4) Quick-change Module Design

Module replacement ≤2 minutes, 0.1mm thickness adjustment

Compatible with M4/M6 threads for various test equipment

3. Technical Parameters Table

Parameter Type | Specific Value |

Applicable Batteries | Cylindrical (18650/21700), prismatic (301480), pouch (≤20mm thickness) |

Clamping Range | φ10-φ30mm (cylindrical)/ ≤150mm side (prismatic) |

Contact Resistance | ≤0.5mΩ (at 100A test current) |

Clamping Force | 5-50N (adjustable) |

Insulation Resistance | ≥100MΩ (500V DC) |

Positioning Accuracy | ±0.05mm (tab center distance) |

4. Application Scenarios

(1) Power Battery R&D Testing

Applicable: 21700 cells, blade batteries, prismatic cells

Solution: Multi-channel design (1-16S) + temperature sensor integration

Value: 30% improved data consistency, 50% faster chucking replacement

(2) Consumer Battery QC

Applicable: 18650/26650 cylindrical, polymer pouch batteries

Solution: High-speed clamping (response ≤0.3s) + auto-align system

Value: 20,000 cells/day per station, false alarm rate <0.1%

(3) Special Battery Environmental Test

Applicable: Low-temperature, high-power density batteries

Solution: Extreme temperature aluminum (-40℃-125℃) + vacuum sealing

Value: Passed ISTA 3A, meets military environmental testing standards

5. Customization Services

(1) Electrical Performance

High-current interface (100-500A testing)

High-frequency impedance adaptation (100kHz-10MHz)

(2) Mechanical Optimization

3D printed prototypes (3-day lead time) for non-standard batteries

Floating clamp design compensates tab height variation (±1.5mm)

(3) Intelligent Integration

Built-in pressure sensor (±1%FS) for real-time force monitoring

Temperature acquisition module (0.1℃ resolution) for thermal runaway warning

6. Quality Assurance

(1) Material Control

Aluminum complies with ASTM B221, each batch with spectro analysis

Conductive parts UL certified, gold plating ≥2μm thickness

(2) Precision Inspection

contact resistance test (Kelvin testing system)

CMM-inspected positioning slots (±0.02mm tolerance)

1000-cycle insertion test, resistance decay ≤10%

(3) After-sales Service

12-month warranty with 2 free calibrations

2h remote support, 24h on-site response for domestic customers

Lifetime supply of wear parts (springs, contacts) at cost price