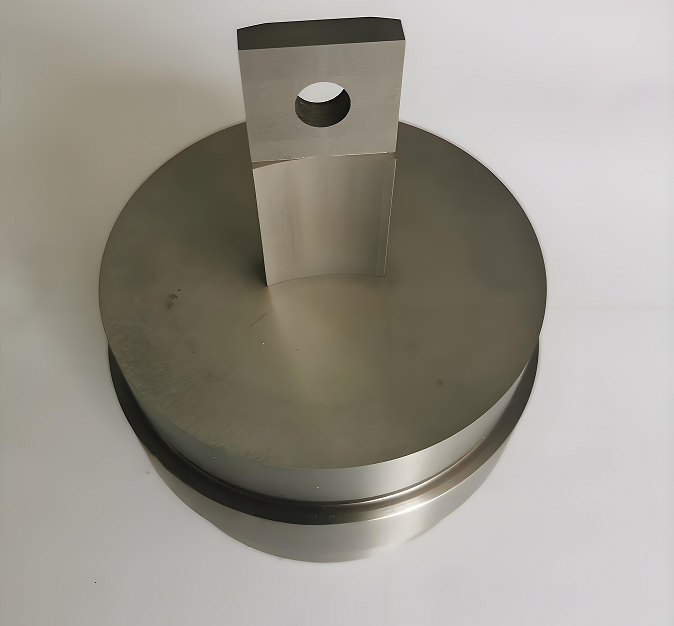

Core Drill Single Segment Cold Press Mould

Product Overview

This single segment cold press mould for core drill bits is specially designed for room-temperature pressing of single core drill segments, replacing traditional hot pressing with cold forming technology. Optimized for high-precision drilling of hard and brittle materials like ceramics and tiles, it achieves precise pressing of single segments at ambient temperature, avoiding thermal damage to diamond abrasives. Suitable for producing single segments of 30-150mm thin-walled drills, especially for small-batch customized orders and R&D sampling.

Product Features

Low-temperature Precision Pressing Process:Using a servo hydraulic system for 0-60 tons constant pressure pressing, segment density uniformity is controlled within ±1.2%, retaining original diamond sharpness, increasing cutting efficiency by 25% compared to hot pressing, while reducing energy consumption by 40%.

High-wear Resistance Composite Material:The cavity is made of DC53 die steel with vacuum quenching + cryogenic treatment, surface hardness reaching HRC64-66. Combined with TD coating technology, anti-adhesion wear resistance is increased by 3 times, capable of withstanding over 80,000 cold pressing cycles, extending mould life to 4 times that of traditional materials.

Single-hole Precision Forming Design:Adopting an independent single-hole cavity structure with laser positioning system, hole position accuracy is controlled within ±0.05mm, segment radial runout ≤0.03mm, meeting high concentricity requirements of thin-walled drills and reducing drilling yaw risks.

Quick-release Single-cavity Structure:The mould uses a modular single-hole design, single cavity replacement time ≤3 minutes. With a manual fine-tuning device, it supports 0.1mm-level hole diameter adjustment, adapting to fast switching of multiple segment specifications, ideal for small-batch multi-variety production.

Technical Parameters

Parameter Type | Specific Value |

Applicable Drill Diameter | 30mm-150mm (special for single segment of thin-walled drills) |

Working Pressure Range | 0-60 tons (servo hydraulic adjustable) |

Mould Working Temperature | Room temperature (5℃-40℃) |

Mould Size | Standard type 400mm×300mm×280mm (customizable) |

Material Combination | Cavity (DC53 quenched steel + TD coating) |

Base (45# steel aged treatment) |

Application Areas

Building Decoration:Cold pressing of tile wall single-hole precision drilling bits and marble countertop drain hole segments;

Ceramic Processing:Low-temperature production of bathroom ceramic single-hole drill bits and mosaic tile cutting segments, avoiding diamond carbonization;

Electronic Industry:Precision pressing of PCB circuit board single-hole positioning drill bits and sapphire substrate hole-opening tools;

R&D Sampling:Small-batch trial production of new diamond formula segments, supporting rapid process verification and parameter optimization.

Customization Services

Customizable single-hole diameter (10mm-100mm) and hole depth (5mm-30mm) to adapt to special drilling needs;

Support for segment matrix density grading (3.5g/cm³-4.0g/cm³) to balance wear resistance in dry/wet cutting conditions;

Customizable cavity surface texture (anti-slip pattern/drainage groove) to optimize chip evacuation and coolant penetration.

Quality Assurance

Complies with ISO 9001:2015 quality management system, each mould undergoes three aging treatments to eliminate internal stress;

Three-coordinate measuring instrument detects cavity precision, hole diameter tolerance controlled within ±0.03mm, surface roughness Ra≤0.6μm;

10-month warranty provided, free replacement of cavity inserts for non-human damage, lifelong cost-price supply of wearing parts, including 1 free pressure system calibration.