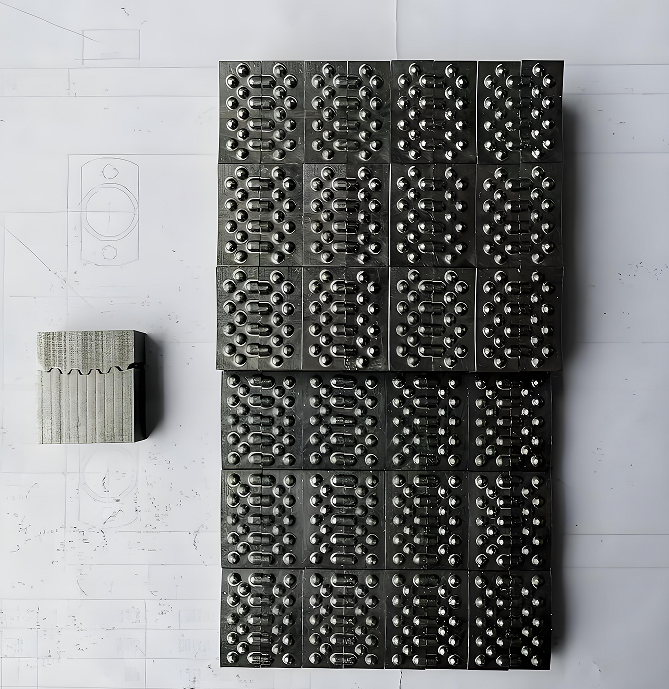

Core Drill Segment U Type

Product Overview

This U-type core drill segment mould is specially designed for segmented hot pressing of core drill bits, optimized for thin-walled drilling scenarios like construction boring and stone hole cutting. The U-shaped groove structure enhances chip evacuation and cooling performance, meeting high-precision drilling requirements for hard and brittle materials such as concrete and tiles, suitable for producing thin-walled drills with diameters of 50-300mm.

Product Features

U-shaped Hydrodynamic Structure:The segment cross-section features a U-shaped groove design, increasing the chip evacuation channel area by 40% compared to traditional structures, and improving debris discharge speed by 50% during drilling, effectively avoiding overheating caused by chip blockage.

Gradient Composite Material:The working surface is sintered with YG8 cemented carbide particles and copper-based binder, while the matrix uses 42CrMo alloy structural steel, combining high hardness (HRA89) and impact resistance, capable of withstanding 80MPa drilling pressure.

Precision Temperature Control System:Equipped with double spiral heating tubes and water-cooled interlayers, achieving precise temperature control within ±3℃ in the range of 350-650℃ via PLC intelligent control, with a hardness uniformity deviation of ≤2% after hot pressing.

Detachable Cavity:Adopting a dovetail groove cavity connection structure with quick 定位 pins, reducing single cavity replacement time to 8 minutes, supporting fast switching production of multiple U-type segment specifications.

Technical Parameters

Applicable Drill Diameter:50mm-300mm (special for thin-walled drills)

Mould Working Temperature:Room temperature-650℃ (segmented heating)

Hot Pressing Pressure:0-80 tons (hydraulic servo control, pressure fluctuation ≤±1.5%)

Mould Size:Standard type 550mm×400mm×350mm (customizable)

Material Combination:Cavity (YG15 cemented carbide insert) + Matrix (42CrMo quenched steel)

Application Areas

Construction Engineering:Production of concrete wall ventilation holes and water-electric pipeline embedded hole drill bits;

Stone Processing:Manufacturing of special drill bits for sink holes and floor drain holes in marble and granite countertops;

Decoration:Forming of hole-opening tools for brittle materials like tiles and glass;

Geological Exploration:Segmented hot pressing of thin-walled core sampling drill bits.

Customization Services

Customizable U-groove depth (3mm-15mm) and opening width (10mm-30mm);

Support for segment matrix formula customization (e.g., diamond concentration, binder hardness);

Development of multi-station linkage moulds for one-time hot pressing of 4-6 segment sections.

Quality Assurance

Complies with ISO 9001:2015 quality management system, each mould undergoes 200 hours of continuous hot pressing testing;

Laser scanning detects U-groove profile accuracy, with dimensional tolerance controlled within ±0.05mm;

10-month warranty provided, free replacement of cavity inserts for non-human damage, and lifelong cost-price supply of wearing parts.