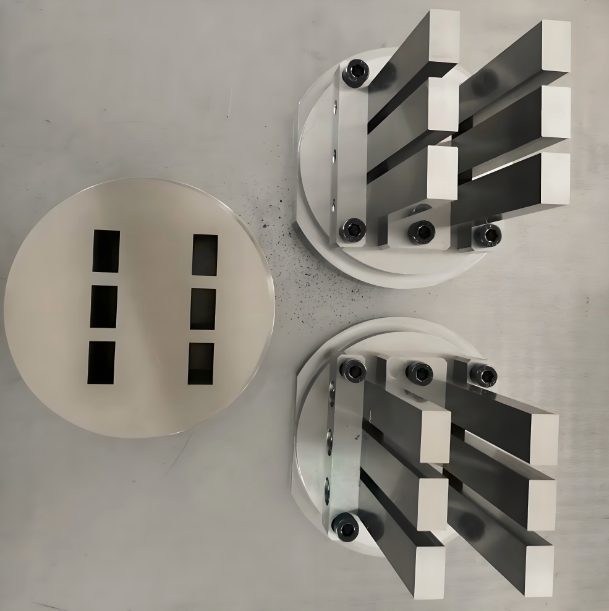

Core Drill Double Segments Cold Press Mould

Product Overview

This double segments cold press mould for core drill bits is specially designed for room-temperature pressing of double core drill segments, adopting dual-cavity synchronous cold forming technology. Optimized for scenarios like concrete wall double-hole construction and stone double-hole docking processing, it achieves simultaneous precise pressing of two segments at ambient temperature, doubling production efficiency compared to single-hole moulds. Suitable for large-scale production of 50-200mm thin-walled drill double segments, especially for batch orders in automated production lines.

Product Features

Dual-cavity Synchronous Pressing Technology:Using a servo hydraulic dual-cylinder drive system for 0-80 tons constant pressure synchronous pressing, double-hole segment density deviation ≤±1.0%, pressing cycle shortened to 12s/group, doubling 产能 compared to traditional single-hole moulds while reducing energy consumption by 35%.

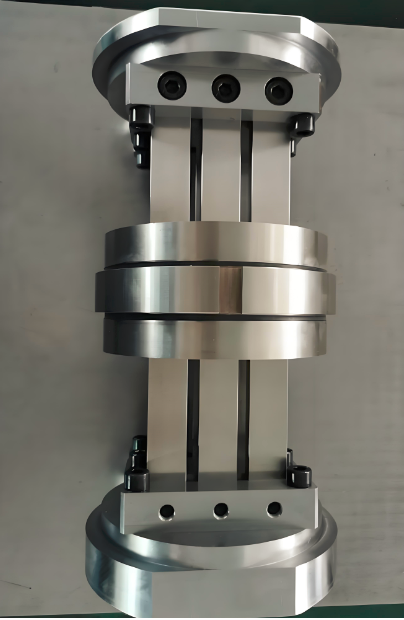

High-wear Resistance Composite Material System:The cavity is made of SKD11 die steel with vacuum quenching + cryogenic treatment, surface deposited with TiCN hard coating (2μm thickness), hardness up to HV2800, fatigue resistance increased by 50%, capable of withstanding 120,000 cold pressing cycles, extending mould life to 3 times that of similar products.

Double-hole Precision Positioning Design:Adopting laser positioning + guide pillar precision guiding structure, double-hole spacing accuracy controlled within ±0.05mm, segment coaxiality error ≤0.03mm, meeting double-hole concentricity requirements of thin-walled drills and reducing drilling yaw risks.

Quick-change Dual-cavity Structure:The mould uses a modular double-hole design, single dual-cavity module replacement time ≤8 minutes. With a hydraulic fine-tuning device, it supports 0.2mm-level hole spacing adjustment, adapting to fast switching of different double-hole segment specifications and compatible with multi-variety small-batch production.

Technical Parameters

Parameter Type | Specific Value |

Applicable Drill Diameter | 50mm-200mm (special for double segments of thin-walled drills) |

Working Pressure Range | 0-80 tons (dual-cylinder servo hydraulic adjustable) |

Mould Working Temperature | Room temperature (5℃-40℃) |

Mould Size | Standard type 600mm×450mm×350mm (customizable) |

Material Combination | Cavity (SKD11 quenched steel + TiCN coating) |

Base (Q345B high-strength steel aged tr |

Application Areas

Construction Engineering:Cold pressing of double-hole drill bits for concrete shear wall ventilation holes and water-electric pipeline embedded double holes;

Stone Processing:Bulk production of double-hole (e.g., faucet hole + soap dispenser hole) drill bits for marble countertops and granite double-groove cutting segments;

Home Furnishing Manufacturing:Low-temperature pressing of double-hole floor drain drill bits for tiles and double-hole ceramic ware hole-opening tools, avoiding diamond carbonization;

Automated Production:Suitable for supporting production of double-hole drill bits for robot drilling units, compatible with automated production line docking.

Customization Services

Customizable double-hole spacing (20mm-150mm) and hole diameter (10mm-80mm) to adapt to special double-hole construction needs;

Support for segment matrix formula customization (e.g., diamond concentration gradient distribution) to meet cutting performance requirements for different materials (concrete/stone/ceramic);

Development of multi-station double-hole moulds (4-hole/6-hole) for one-time pressing of multiple segment groups, further improving large-scale production efficiency.

Quality Assurance

Complies with ISO 9001:2015 quality management system, each mould undergoes four aging treatments to eliminate internal stress;

Three-coordinate measuring instrument detects double-hole position accuracy, hole spacing tolerance controlled within ±0.03mm, surface roughness Ra≤0.4μm;

12-month warranty provided, free replacement of cavity modules for non-human damage, lifelong cost-price supply of wearing parts, including 2 free pressure system calibrations.